Wuxi Longterm Machinery Technologies Co., Ltd offers the complete turnkey solutions for producing the various types of cooking and industrial LPG cylinders from the beginning to the end, the LPG cylinder manufacturing process includes handle & base ring forming line, blanking and body forming line, welding, heat treatment & hydrostatic testing machine, surface coating &finishing line, and other auxiliary testing equipment, like X-RAY testing, chemical analyze instrument, burst testing, etc.

We dedicate ourselves into this field many years and own the professional team to provide all-sided service, for instance,

we are able to design the cylinder drawing according to different standards, DOT, SON; we can provide the facility foundation drawing to ensure the line will attain the highest productivity; we can provide the timely installation and commissioning service for our clients, we will send the skilled engineers to assist the installation as long as the machines are in position, in order to help our clients run the whole line as earlier as possible; meanwhile, our after-sales person is online 24 hours to solve your urgent problems. Additionally, We have semi-auto and full-auto machine configuration which could be customized according to the daily output and budget, the standard daily output we deal the most are 1000 pcs per 8 hours and 2000 pcs per 8 hours. All in all, the satisfaction of the clients is our motivation to go full steam ahead!

Interested in LPG Cylinder Making Machine from Longterm?

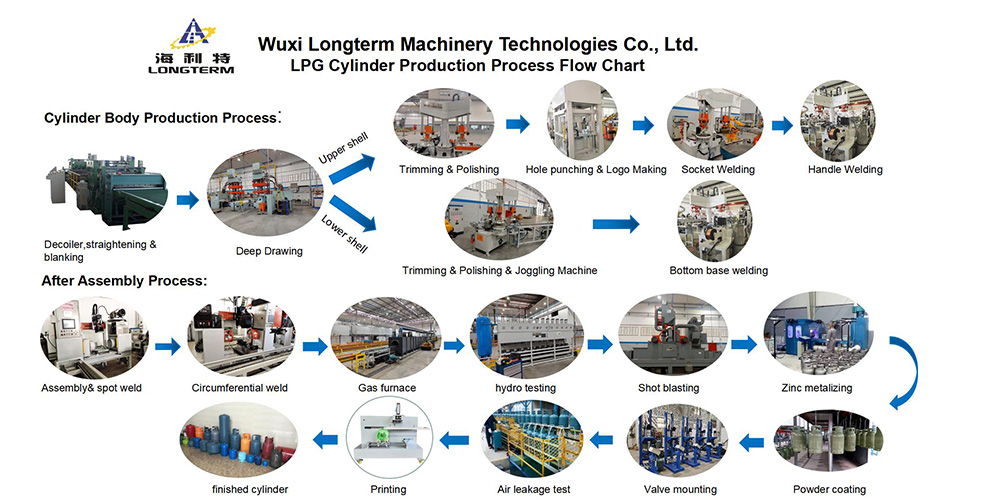

The entire LPG cylinder production line involves several process steps starting from parts forming to final testing. The following is the LPG cylinder manufacturing process:

- Handle/Collar production line

- Foot ring production line

- Body production line

- Blanking and deep drawing

- Welding line

- Heat treatment and hydrostatic testing line

- Surface process line, incl. Shot blasting, zinc metalizing, powder coating

- Finishing line, incl. Valve mounting, leakage testing, silk printing

- Energy station, incl. LPG tank, air compressor, mixed gas tank

- Testing equipment, inch. X-ray testing, chemical analyse instrument, burst testing and other auxiliaries

We do have the obvious strength compare with other machine manufacturers in some machines, for instance, we adopt MIG welding technology for cylinder body welding, it saves at least 50% of welding material compare with SAW welding, the welding wire we use is 1.2mm and one-pass welding is enough to ensure the welds strength. Meanwhile, our machine is a full-auto system that connects by conveyors and mechanical arms, one operator is able to take care of 6 sets of the machine simultaneously.