We are a professional manufacturer of LPG cylinder production line machine with more than 30 years of history. We provide customers with valued solutions including hydraulic press drawing, blanking line, longitudinal seam welding, circumferential welder, nozzle welding, powder coating line, hydro testing machine, shot blasting equipment, etc.. We are improving technologies all the time and developing the welding machinery market. Due to highly automatic, simple operation and reliable quality welding equipment, they are popular and well-accepted in many industries.

Our machinery has been exported to many countries, such as Bangladesh, Russia, the US, Australia, Turkey, Vietnam, India, Ukraine, Mexico, etc.. We are the Longterm Company, we will provide Longterm Quality Machinery and Longterm cooperation for customers from all over the world.

-What’s the LPG (liquefied Petroleum Gas)?

Liquefied petroleum gas or liquid petroleum gas (LPG or LP gas) is a flammable mixture of hydrocarbon gases used as fuel in heating appliances, cooking equipment, and vehicles.

What we are sharing here is cooking LPG cylinder, this kind of cylinders are used in many countries for economic reasons, for convenience or because it is the preferred fuel source.

To boil, the liquid LPG draws heat from the steel walls of the LPG gas cylinder (propane tank) which, in turn, works by getting heat from the ambient air. LPG liquid boils and turns back into gas vapor when you release some of the pressure in the gas bottle (propane tank) by turning on your gas appliance.

- The processes for making an LPG cylinder

The entire processes for making a new LPG cylinder could be divided into several main parts:

C: Cylinder body production line: Include the blanking line to make the round sheet, hydraulic presser to draw the end dish, welding line to weld together the end dishes, heating furnace to remove the material stress, hydrostatic testing line to inspect the cylinder quality, shot blasting, zinc metalizing, powder coating to process the cylinder surface.

D: Testing equipment: Include the X-ray testing, burst testing, chemical analysis testing, universal testing, all these tests can ensure the raw material and cylinder quality.

E: Energy station: Include the LPG tank, air compressor, mixed gas tank, these tanks are supplying the energy to the machine during the running, like LPG tank supplies the gaseous LPG to the heating furnace and drying oven of the powder coating line, mixed gas tank supplies the argon and CO2 to the welding line.

- Which process will influence an LPG cylinder quantity?

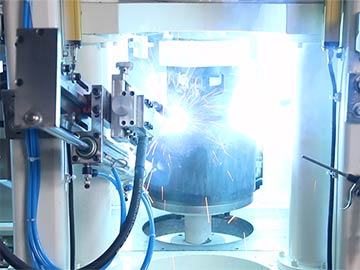

While making a new cylinder, some processes are rather important that will influence the cylinder quality. As per our several turnkey lines’ experience, the most important part is the body welding. In China, all cylinder manufacturers will select 1 cylinder from one batch (1000 pcs) to do X-RAY testing, if the cylinder sample can’t pass the test, then all this batch cylinders have to be rechecked, it definitely will decrease the working efficiency and waste the manpower. Meanwhile, some people are still using SAW (Submerged Arc Welding) technology that leads to material and manpower loss, and SAW has a strict requirement for the operator. Whereas our body welding lines adopt MIG welding can save welding wire around 20%, and improve the working efficiency up to 30%, one operator can take care of 6 sets simultaneously, the whole welding process is implemented by PLC, and the operator only needs to replace the welding wire when it’s used up.

Not only the body welding, but other parts also will affect the cylinder quality, like the heating furnace, hydrostatic testing machine, powder coating line, each part must be guaranteed to get a perfect cylinder, and that’s our mission for you!

Do you want to know about the LPG Cylinder Production Line from longterm?

- Our machine technology advantage

With rich experience, we are improving our machine technology all the time to catch up on the world market, and we are willing to share our advanced technology to help this industry grow. We attend the relevant summit and Vitis the different clients which really stimulates our notion to make some improvements. I’m willing to list some of our progressive machines:

- Cylinder bodying welding line: MIG welding, 60 seconds for one pass, 6 sets machines can weld 2000 pieces cylinder per 8 hours and only one operator is required to take care of all machines. Saving the welding material by using 1.2mm solid welding wire, and automatic tracking system (video + laser) to ensure the quality of the weld.

- Online hydrostatic testing machine: 12 cylinders can do the testing simultaneously, and each cylinder’s testing report will be recorded in the computer chips for the future appliances.

- Powder coating line: Automatic powder spraying system with the high-quality torch, and equips with the circulating system to minimize the power loss.

- Heating furnace: We supply both annealing and the normalizing furnace for different requirements, and equips the heat recycling system to save energy.

- The future prospect of LPG

Obviously, LPG will become more popular energy in the coming future due to its economy and protect the environmental advantages. Currently, after we attend the LPG summits in some Asian and African countries, we realized that LPG cylinder demands would definitely increase rapidly in the coming few years to replace the traditional energy, like wood, coal, etc. Meanwhile, most governments issue the beneficial policy to encourage people to use LPG cylinder, therefore more and more investors are coming up for this business, and with our unsurpassed service, we do help several clients to start their own cylinder business smoothly in the market, such as Vietnam, Bangladesh, India, Nigeria, Ghana, etc. We have much confidence to providing you the best support if you are interested in LPG cylinder production line, please contact us freely!